How does the design of a custom lock cylinder impact its resistance to picking and tampering?

The design of a custom

brass alloys lock cylinder plays a crucial role in determining its resistance to picking and tampering. Several design features can enhance the security of a lock cylinder and make it more difficult for unauthorized individuals to manipulate or bypass. Here are key design elements that impact resistance to picking and tampering:

Pin Tumbler System:

The use of a high-quality pin tumbler system is fundamental to a secure lock cylinder. Custom lock cylinders often employ multiple pins with varying lengths, creating a complex keying system that adds an extra layer of difficulty for would-be pickers.

Keyway Design:

Unique and complex keyway designs can significantly enhance security. Custom keyways, especially those with irregular shapes or restricted access points, make it more challenging for picking tools to manipulate the pins inside the lock.

Master Key Systems:

While master key systems provide convenience, they can also introduce vulnerabilities. Custom lock cylinder designs should carefully implement master keying to minimize the risk of compromise and ensure that master keys cannot easily be replicated.

Anti-Pick Pins:

Lock cylinders can be equipped with anti-pick pins that are specifically designed to resist picking attempts. These pins often have serrated edges, mushroom-shaped heads, or other features that make it more difficult for traditional lock-picking tools to manipulate them.

Security Pins:

Incorporating security pins, such as spool or mushroom pins, adds complexity to the locking mechanism. These pins are designed to disrupt the picking process by creating false sets and making it more challenging for picking tools to control and manipulate the pins.

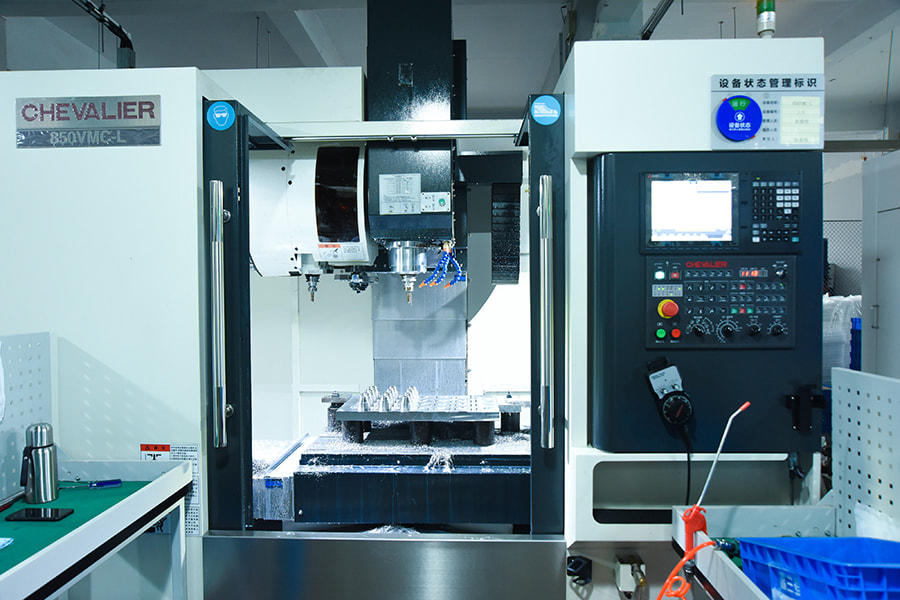

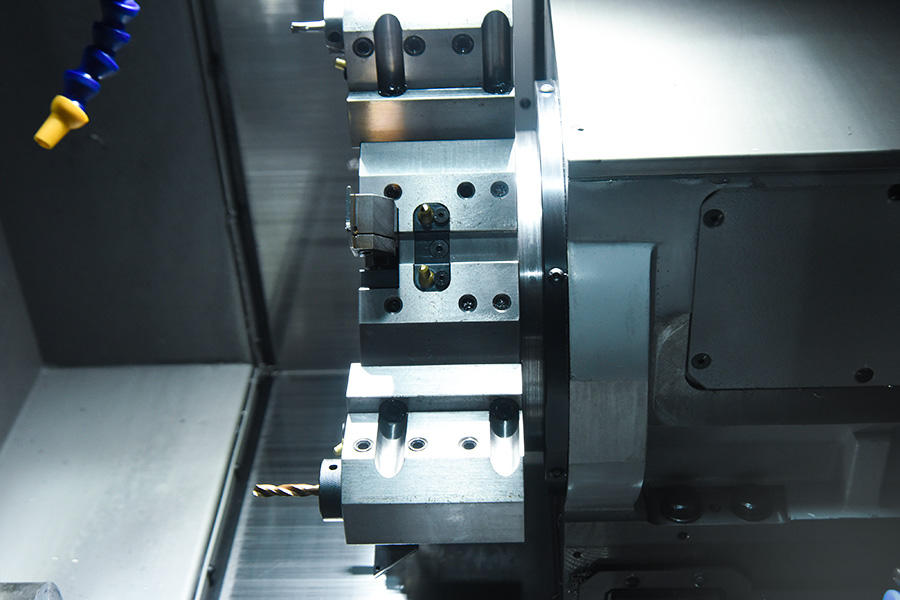

Materials and Construction:

High-quality materials and precision manufacturing contribute to the overall security of the lock cylinder. Materials resistant to drilling and cutting, along with tight tolerances in the manufacturing process, make it more difficult for tampering tools to compromise the lock.

Key Control:

Effective key control measures are critical. Custom lock cylinders should implement key control systems that restrict unauthorized key duplication, preventing the use of unauthorized copies to gain access.

Rotational Resistance:

The design should include features that resist rotational manipulation. For instance, anti-drill plates or components that resist torque attacks can enhance the overall resistance to tampering.

Electronic Security Features:

In modern custom lock cylinder designs, electronic security features such as integrated sensors, alarms, or anti-tamper circuitry can provide additional layers of protection against manipulation attempts.

Modular Components:

Some custom lock cylinders incorporate modular components that resist disassembly or swapping of parts, making it more difficult for tamperers to manipulate the lock.