How Stainless steel Hexagon Flange Nuts Streamline Assembly Processes?

Stainless steel hexagon flange nuts play a crucial role in streamlining assembly processes across various industries. Here's how these nuts contribute to efficiency in assembly:

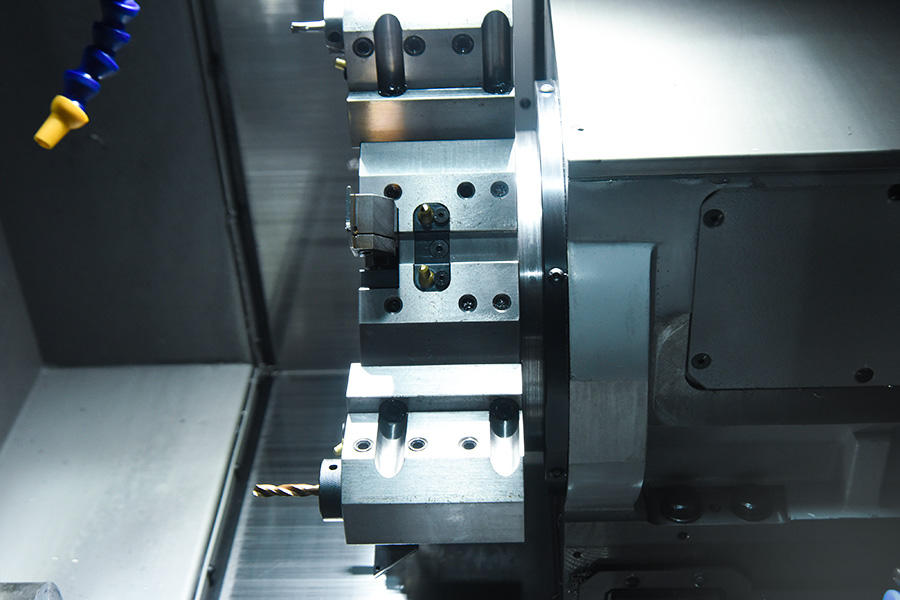

Easy Handling and Installation:

The integrated flange on steel hexagon flange nuts provides a larger surface area for gripping and tightening. This feature facilitates easy handling during manual or automated assembly processes, reducing the time and effort required for installation.

Tool-Free Installation:

Hexagon flange nuts are designed for hand-tightening, allowing for tool-free installation in many applications. This simplifies the assembly process, eliminating the need for additional tools and streamlining the workflow.

Reduced Risk of Over-Tightening:

The flange acts as a built-in washer, providing a stable surface against which the nut can be tightened. This design helps prevent over-tightening, ensuring that the nut is securely fastened without damaging the components, which can be particularly important in delicate assemblies.

Enhanced Stability and Security:

The flange distributes the clamping force over a larger area, offering enhanced stability. This design feature minimizes the risk of nuts coming loose during operation, promoting the overall security and reliability of the assembled components.

Time Efficiency in High-Volume Production:

In high-volume manufacturing settings, the ease of handling and installation of hexagon flange nuts contributes to significant time savings. The simplicity of the assembly process allows for faster production cycles, improving overall efficiency.

Vibration Resistance:

Hexagon flange nuts are effective in applications where vibration is a concern. The flange provides additional resistance to loosening caused by vibrational forces, ensuring the long-term stability of assembled components in dynamic environments.

Consistent Torque Application:

The design of hexagon flange nuts allows for consistent torque application, promoting uniform clamping force across multiple fasteners. This consistency is essential in achieving reliable and repeatable results in assembly processes.

Space-Saving Design:

The integrated flange eliminates the need for a separate washer, reducing the number of components in the assembly. This space-saving design is particularly advantageous in applications with limited space or where weight considerations are crucial.

What application versatility do Steel Hexagon Flange Nuts have?

Steel Hexagon flange nuts are versatile and can be used in a wide range of applications. Their streamlined design makes them suitable for both general-purpose and specialized assembly processes across industries such as automotive, construction, electronics, and machinery.

Enhanced Aesthetics and Finish:

The flange on hexagon flange nuts can provide a finished appearance in exposed assemblies. This can be beneficial in applications where aesthetics are important, contributing to a polished and professional look.

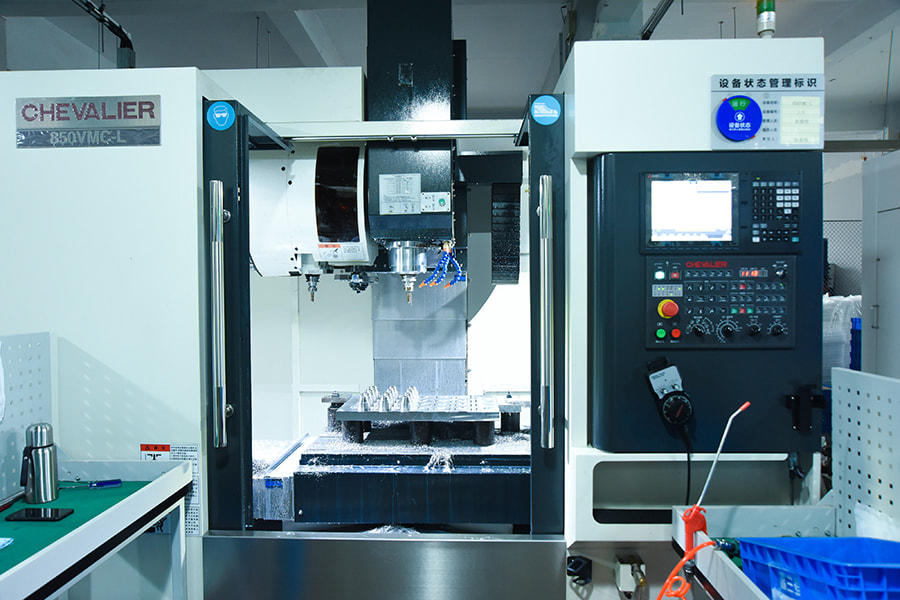

Compatibility with Automated Systems:

Steel Hexagon flange nuts are compatible with automated assembly systems. Their standardized design allows for seamless integration into automated production lines, further optimizing efficiency in large-scale manufacturing operations.

Cost-Effective Solution:

The efficiency gained from streamlined assembly processes, reduced need for additional components, and ease of handling contribute to cost savings. Hexagon flange nuts offer a cost-effective solution without compromising on performance.

Steel Hexagon flange nuts streamline assembly processes by offering ease of handling, tool-free installation, enhanced stability, and versatility in various applications. Their design features contribute to time and cost efficiency, making them a valuable component in modern manufacturing and assembly operations.